Oracle Apps R12 OPM, SCM, INV, Procurement, OM Modules Functional and Technical Solution by Razaul Karim Reza

Translate

Wednesday, May 11, 2016

Sunday, February 14, 2016

Interface Trip Stop – SRS Program

The Interface Trip Stop (ITS) will be triggered at the time of Ship Confirm if the check box ‘Defer Interface’ is not checked. ITS can also be executed from concurrent request.

Interface Trip Stop does the following things,

- Updating the Order Management Data (OE_ORDER_LINES_ALL)

- Triggering the Inventory Interface (to update the Inventory tables)

ITS updates the following fields on OE_ORDER_LINES_ALL table:

- Shipped_Quantity

- Shipping_Quantity

- Actual_Shipment_Date

Inventory Interface will be triggered only if the first part, that means related to OM has successfully completed and flag OE_INTERFACED_FLAG = ‘Y’ on WSH_DELIVERY_DETAILS.

If

value of this flag is N/P then Inventory Interface will never be

triggered. And even if you try to submit the Inventory Interface - SRS,

delivery detail with OE_INTERFACED_FLAG =’N’ will never be picked up.

OE_INTERFACED_FLAG = Y -- signifies ITS has interfaced shipping data to OM

INV_INTERFACED_FLAG = Y -- signifies ITS has interfaced shipping data to INV

As mentioned earlier if the ‘Defer Interface’ checkbox is checked then Interface trip stop concurrent will not be triggered automatically, we should run it manually.

Navigation:

Oracle Order Management > Shipping > Interfaces > Run

Select Mode as ‘All’

If you want to process a particular transaction, then select the same from the list of values of ‘Trip Stop’ and ‘Delivery’.

If wanted to process all the pending transactions leave the fields blank and submit the concurrent.

As

scheduling other concurrent’s, we can also schedule ITS – SRS process

to run at regular intervals to process different trip stops.

But keep in mind that Deadlock errors may occur when multiple Interface trip stop processes are running at the same time.

To avoid this we have to make ITS and ITS-SRS processes incompatible with themselves as follows,

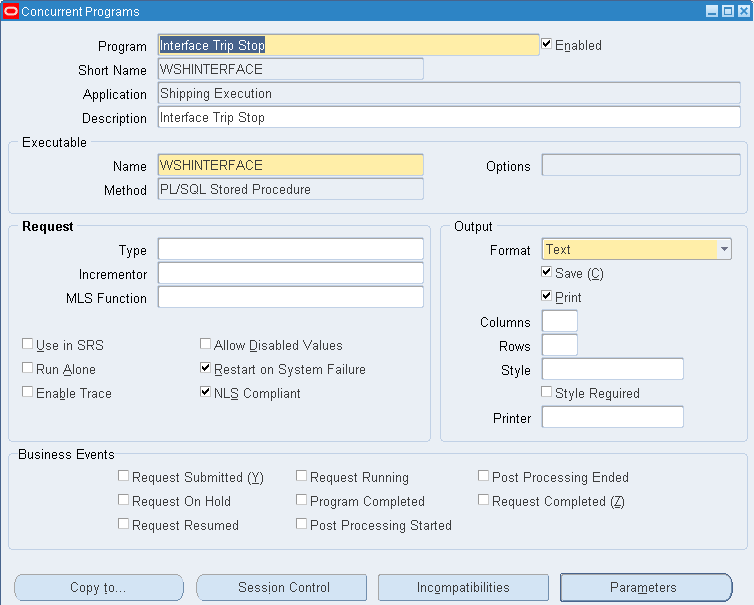

Navigation: Application Developer > Concurrent > Program

Query ‘Interface Trip Stop – SRS’ program, Click ‘Incompatibilities’ box.

In the Name field select ‘Interface Trip Stop’.

For ‘Scope’ select ‘Program’ and for ‘Type’ select ‘Global’. If you

select 'domain' for type, then the system will allow two ITS processes

to run simultaneously if they are run in different domains.

Now Query ‘Interface Trip Stop’ and make it incompatible with ‘Interface Trip Stop – SRS’ in the same way as above.

This

will prevent more than one ITS or ITS-SRS process from running at the

same time. All other ITS or ITS-SRS processes will be added to a queue

and will be processed when the current ITS or ITS-SRS process completes.

Therefore, multiple ITS processes will not become deadlocked with each

other.

Tuesday, February 9, 2016

Inventory Cost Accounting Method selection for a Manufacturing Organization: Average Vs Standard Costing

---------------------------------------------------------

Download White Paper: Inventory Cost Accounting Method selection for a Manufacturing Organization: Average Vs Standard Costing

Oracle Process Manufacturing - Implementation Questionnaire

Inventory

--How many different products within the product line?

--Total how many ingredients and byproduct items present within the product line?

--Are there any intermediate items which are stocked in inventory?

--What are the main inventory keeping locations within the manufacturing plant

--Are Finished Goods Lot and Grade controlled?

--Are Raw Materials Lot and Grade controlled?

--What are the main unit of measures used?

--Is the stock tracking done in multiple units for the same item?

--Are different pack-sized Finish Products treated as different Items / SKUs?

--Is the shelf life maintained for different ingredients / products ?

--FG Storage happens in same warehouse or different?

--Reusable waste Storage locations?

--Are the Co-products produced during batch processing?

--Whether Items have Version control?

--Lot numbering/sequencing?

--How are packaging materials defined in inventory - Diff. item codes for diff type of containers / packaging?

--On what basis the material is moved from main storage to production floor?

Product Development

--Do multiple formulas / recipes exist for one product?

--Version control for formulas, recipes and routings?

--Codification logic for formulas, recipes ?

--How frequently does the formula / recipe change ?

--Process loss information available in formulas?

--Are scrap / waste items defined and used in formulas?

--Creation and Approval process of Recipe/Formula?

--How packaging waste is handled?

--Is there any tracking of technical parameters / process parameters like moisture content etc.in formulas / recipes?

--Are formula / recipes maintained in baan system ? Availability of data?

--Is the resource (equipment/man-power etc.) tracked in the system ; data availability?

--Are routings (operation steps) maintained in the system; availability of data?

--Are the packing materials defined as a part of formula?

Process Execution

--What % of production is MTO?

--What is the basis for daily production - Manual / System generated production schedule ?

--How many batches are processed within a day?

--Finished Good is produced through a single batch or a series of batches for different intermediates?

--What arte the intermediates which are stocked in inventory?

--Is there any sub-contracting process involved?

--How is production data captured presently? -- Through system driven batch execution or manually in excel sheets?

--How frequently production data is captured?

--What all information is captured for production?

--What is the general range of batch size?

--How is scrap generation and rejection process handled?

--How is rework process handled?

--How many shifts of production? Is there 24 Hr operation?

--Are the production batches linked to sales orders in "Make To Order" scenario

--Automatic numbering of batches?

--How is process loss tracked?

--Any inventory keeping locations within the production line or continuous process?

--How is variance tracking (between planned and actual usage - material / resources) done for production batches?

--What are the interaction points of production department with other departments?

--What all PLC / equipments linked to prouction system?

--What is the WIP reconciliation process followed at period ends?

Quality Control

--What are the different stages of quality inspection?

--How is the quality inspection data recorded - Manual or system ?

--Is the material tagged with quality grades after quality inspection?

--How is rejected item treated, what is the process followed for the same?

--Item / Vendor / Customer quality specifications maintained in the system ?

--Is quality inspection done on the basis of sampling plans?

--Criteria for defining inspection samples and conducting quality checks?

--Material expiry and shelf life tracking ?

--Quality department structure?

--How is communication managed between quality and other departments?

--Any approval methodology followed within QC ?

Costing

--Costing method for raw materials?

--Costing method for Finished goods?

--How is resource cost (equipment, man-power) tracked? Is it a part of FG direct cost?

--How is overhead cost managed ? Tracked at an aggregate level or product level?

--Present accounting process for production related transactions?

--How many different products within the product line?

--Total how many ingredients and byproduct items present within the product line?

--Are there any intermediate items which are stocked in inventory?

--What are the main inventory keeping locations within the manufacturing plant

--Are Finished Goods Lot and Grade controlled?

--Are Raw Materials Lot and Grade controlled?

--What are the main unit of measures used?

--Is the stock tracking done in multiple units for the same item?

--Are different pack-sized Finish Products treated as different Items / SKUs?

--Is the shelf life maintained for different ingredients / products ?

--FG Storage happens in same warehouse or different?

--Reusable waste Storage locations?

--Are the Co-products produced during batch processing?

--Whether Items have Version control?

--Lot numbering/sequencing?

--How are packaging materials defined in inventory - Diff. item codes for diff type of containers / packaging?

--On what basis the material is moved from main storage to production floor?

Product Development

--Do multiple formulas / recipes exist for one product?

--Version control for formulas, recipes and routings?

--Codification logic for formulas, recipes ?

--How frequently does the formula / recipe change ?

--Process loss information available in formulas?

--Are scrap / waste items defined and used in formulas?

--Creation and Approval process of Recipe/Formula?

--How packaging waste is handled?

--Is there any tracking of technical parameters / process parameters like moisture content etc.in formulas / recipes?

--Are formula / recipes maintained in baan system ? Availability of data?

--Is the resource (equipment/man-power etc.) tracked in the system ; data availability?

--Are routings (operation steps) maintained in the system; availability of data?

--Are the packing materials defined as a part of formula?

Process Execution

--What % of production is MTO?

--What is the basis for daily production - Manual / System generated production schedule ?

--How many batches are processed within a day?

--Finished Good is produced through a single batch or a series of batches for different intermediates?

--What arte the intermediates which are stocked in inventory?

--Is there any sub-contracting process involved?

--How is production data captured presently? -- Through system driven batch execution or manually in excel sheets?

--How frequently production data is captured?

--What all information is captured for production?

--What is the general range of batch size?

--How is scrap generation and rejection process handled?

--How is rework process handled?

--How many shifts of production? Is there 24 Hr operation?

--Are the production batches linked to sales orders in "Make To Order" scenario

--Automatic numbering of batches?

--How is process loss tracked?

--Any inventory keeping locations within the production line or continuous process?

--How is variance tracking (between planned and actual usage - material / resources) done for production batches?

--What are the interaction points of production department with other departments?

--What all PLC / equipments linked to prouction system?

--What is the WIP reconciliation process followed at period ends?

Quality Control

--What are the different stages of quality inspection?

--How is the quality inspection data recorded - Manual or system ?

--Is the material tagged with quality grades after quality inspection?

--How is rejected item treated, what is the process followed for the same?

--Item / Vendor / Customer quality specifications maintained in the system ?

--Is quality inspection done on the basis of sampling plans?

--Criteria for defining inspection samples and conducting quality checks?

--Material expiry and shelf life tracking ?

--Quality department structure?

--How is communication managed between quality and other departments?

--Any approval methodology followed within QC ?

Costing

--Costing method for raw materials?

--Costing method for Finished goods?

--How is resource cost (equipment, man-power) tracked? Is it a part of FG direct cost?

--How is overhead cost managed ? Tracked at an aggregate level or product level?

--Present accounting process for production related transactions?

Oracle Process Manufacturing (OPM) – Setup Quickie!!

Oracle Process Manufacturing (OPM) – Setup Quickie!!

This post is first in a series of

Quick reference guides which I term as “Quickie”. This quickie has been created

with an objective of providing an easy step-by-step reference guide for OPM

Setup steps across different OPM modules (Oracle Applications – e Business

suite Release 12). Details for each step are widely available in User

guides and installation guides published by Oracle. The Quickie can also

act as a good tracking tool for OPM setup activities. If you find this helpful,

please do leave a comment.

| Inventory | |

| 0 | Define and build Inventory Calendar |

| 1 | Define Inventory Organization |

| 2 | Org Parameters |

| 3 | Subinventories |

| 4 | Locators |

| 5 | UOM Classes |

| 6 | UOMs |

| 7 | Define Items |

| 8 | Picking Rules |

| 9 | Pick Slip Grouping Rules |

| 10 | Org Access Setup (After full configuration is done) |

| OPM Costing | |

| 1 | Define Cost type |

| 2 | Define Cost Calendar |

| 3 | Define Component Group |

| 4 | Define Cost Analysis |

| 5 | Costing Org Association |

| 6 | Fiscal Policy |

| 7 | Assign Ledger |

| 8 | Percentage overhead |

| 9 | Defining resource cost |

| 10 | Fixed overhead (resource overhead) |

| 11 | Rollup Source e Organization |

| Sub-Ledger Accounting (SLA) | |

| 1 | Create account derivation rule along with conditions |

| 2 | Journal line definition |

| 3 | Applications Accounting Definition (AAD) |

| 4 | Associate the AAD with the Sub ledger Accounting Method |

| 5 | Assign this SLAM to the Ledger. |

| System Administrator | |

| Profiles | |

| 1 | TCF:Host |

| 2 | TCF:Port |

| OPM Product Development Security Manager | |

| 1 | Organization Parameters |

| 2 | Profile Options |

| 3 | Security Control |

| 4 | Setup Laboratory Organization |

| OPM Product Development Security Profile Manager | |

| 1 | Security Profiles |

| OPM Product Development | |

| 1 | Technical Parameters |

| 2 | Density Technical Parameter (Must – Ratio between base mass uom and base volume uom) |

| 3 | GMD: Density Profile |

| 4 | GMD: Technical Parameter Category Set |

| 5 | Technical Parameters Sequence |

| 6 | Item Technical Data |

| 7 | Technical classes and sub-classes |

| 8 | Master Creation (Formulas, activities, recipes etc.) |

| 9 | Simulator can be run to update the user defined parameters |

| OPM System Administrator | |

| 1 | Paragraph setup |

| 2 | Session Parameters |

| 3 | Reason codes, document types, nos. can be viewed |

| 4 | Tokens |

| 5 | Workflow Process Activation and configuration |

| Bill of Materials | |

| 1 | Setup Workday Calendar |

| OPM Process Execution | |

| 1 | Setup Parameters |

| 2 | Make to Order Rules |

| 3 | Profile Options |

| OPM Process Quality | |

| 1 | Process Quality enabled items |

| 2 | Lot, Status and Grade control item attributes |

| 3 | Setup Action Codes (user actions to be performed for out of specification results) |

| 4 | Setup Grades |

| 5 | Review / edit material status closed (lots can be assigned different statuses based on quality results and inspection) |

| 6 | Reason code access |

| 7 | Setup specifications (at customer order level, item level etc.) |

| 8 | Setup Tests |

| 9 | Test Classes |

| 10 | Test Groups |

Saturday, February 6, 2016

Oracle OPM product Strengths

For those who are very new or not aware to Oracle OPM product, here are some of high points of Operational Functionality that product offered.Moreover there is significant changes has been seen in age of internet that has re-defined the operation of the supply chain(SCM) thus Oracle OPM Products too.

Please Check with Oracle OPM Page, to see what are the recent changes has been incorporated. based out of my exposure very long time back, these are the functionlity that product had.

- Lot Traceability :In this some features like Lot/Sub lot,Forward/Backward Genealogy,Status Control

,Grade Control,Lot Expiration,Allocation for Shelf Days - Multiple Formulas (Bills) :These are typically used

for formulas for production, costing planning, MSDS,Effectivities By

Date for Seasonality,Effectivities by Quantity,Scaling,Alternate

Routings,

Scrap factors and theoretical yield - Support for A and V type Formulas : All three kind of formula like well suited here:

- V Bills are constructive- Multiple ingredients one product

- A Bills are destructive- One ingredient, multiple products

- A Bills support co-products and- by-products

- Ingredient Substitutions

- The features like mass ingredient substitutions for formulas

- Designed for ingredient substitutions in manufacturing orders (batches)

- Manufacturing variances for substitutions tracked and reported.

- Dual UOMs functionlity

- Item specific UOMs

- Count to Mass

- Count to Volume

- Mass to Volume

- User defined UOM types

- Lot specific UOMs

- Dual UOM Types

- Fixed

- Defaulted with tolerance

- No relation

- Uses

- Sell by count, invoice by weight

- Dry pounds, wet pounds

- % solids, % moisture

- Item specific UOMs

- Specification Matching Functionlity

- Some of the great features like

- QC Specs and Results : This may be based out of vendor,customer,plant or by lot

- There was yet another feature for customer spec matching.

- Regulatory Compliance

- Material Safety Data Sheets (MSDS) are configurable, also formulas for MSDS

- Other features are flexible Costing, which can be either processIf Costing (Standard,Actual) or Organization Level basis (Warehouse,Item)

What you should know about Oracle OPM products

Oracle OPM designed exclusively for catering the business need for process manufacturers industry like:

- Consumer Packaged Goods

- Food, Beverage, Health and Beauty, Household Products

- Industrial Products

- Chemical, Pharmaceutical, Petroleum, Metals, Mining, Paper and Glass

Is there any difference from Oracle Discrete Manufacturing?

Yes, there is ..If you came from Discrete manufacturing background, these are one -to-one mapping between modules.

Subscribe to:

Comments (Atom)

Item Rate Update for Stock In Trade - Returnable Receive/Return (Loan)

Stock In Trade - Returnable Receive/Return (Loan)

-

Oracle Apps R12 Subledger Accounting Tables and joins XLA Table joins GL_JE_BATCHES (je_batch_id) => GL_JE_HEADERS...

-

Stock In Trade - Returnable Receive/Return (Loan)

-

Oracle Forms: How to select multiple records in a block using a Record Group I decided to create this demo because the question of how to s...